| Availability: | |

|---|---|

| Quantity: | |

CS-AVS

CHANG SHENG

8428399000

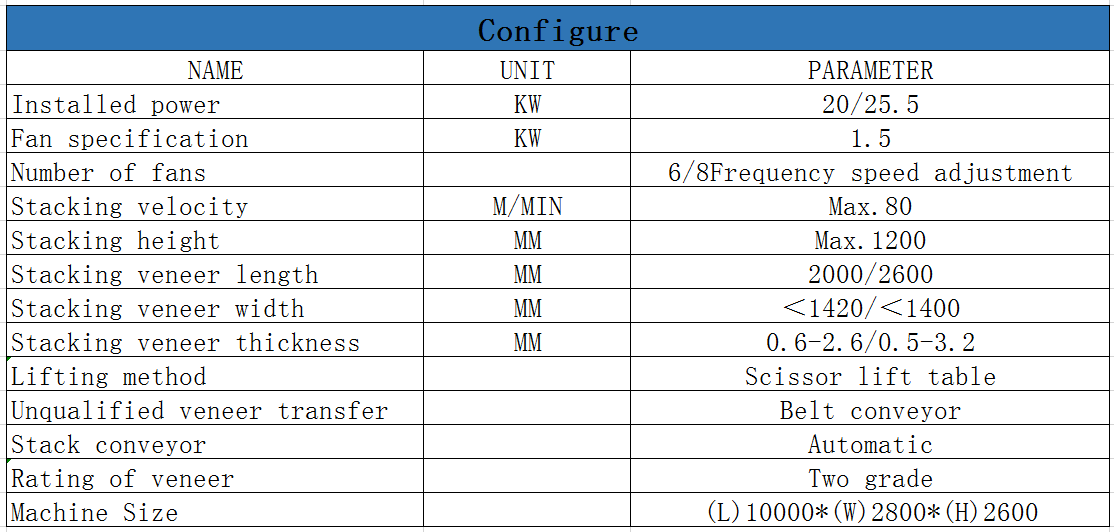

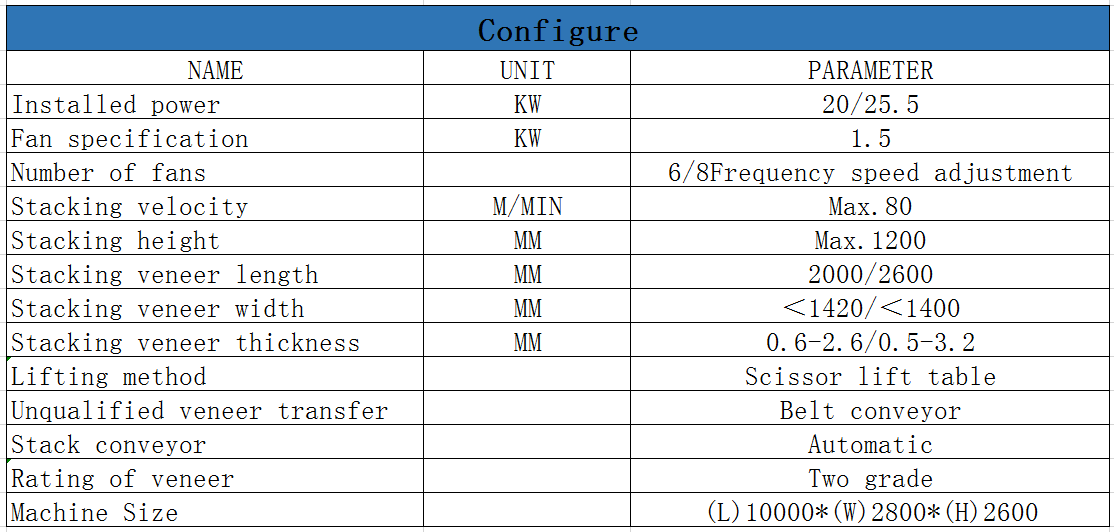

Automatic vacuum core veneer stacker

This machine takes the veneer from the rotary clipper and stacks them according to size.

1.It's function is to pile up the cut veneer automaticlly, commonly installed after veneer peeling machine to save labour cost and improving working efficiency.

2.High quality, the machine has been tested and upgraded several time, production sill mature and quality guaranteed

3.With First and Second Grade Veneer Grading and Sorting System.

pre-sale service

We provide best service according to your demand, such as prophase plan, examine on the spot, process flow design , customized equipment, design solution for complete production lines and operator training etc.

Service during the sales:

Send technicians to the customer's factory to install and debug the machine on site, train operators for free and you can also come to our factory to learn for free.

After-sale services:

We provide one year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replancements can be shipped to your right away.

7 peoples

We have a professional after-sales service team with 7 professional technicians.There are 300 working days a year to serve customers.

20 years

We have been engaged in woodworking machinery for 20 years and have extensive industry experience.

365 days

We are waiting for your call for 365 days, providing you with services such as purchase and support.

3000 customers

More than 3,000 customers purchase our equipment and are satisfied with the equipment and service.

10000 experiments

Our factory has conducted more than 10,000 innovative experiments since its inception.

Only to produce the most suitable equipment for the customer.

Automatic vacuum core veneer stacker

This machine takes the veneer from the rotary clipper and stacks them according to size.

1.It's function is to pile up the cut veneer automaticlly, commonly installed after veneer peeling machine to save labour cost and improving working efficiency.

2.High quality, the machine has been tested and upgraded several time, production sill mature and quality guaranteed

3.With First and Second Grade Veneer Grading and Sorting System.

pre-sale service

We provide best service according to your demand, such as prophase plan, examine on the spot, process flow design , customized equipment, design solution for complete production lines and operator training etc.

Service during the sales:

Send technicians to the customer's factory to install and debug the machine on site, train operators for free and you can also come to our factory to learn for free.

After-sale services:

We provide one year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replancements can be shipped to your right away.

7 peoples

We have a professional after-sales service team with 7 professional technicians.There are 300 working days a year to serve customers.

20 years

We have been engaged in woodworking machinery for 20 years and have extensive industry experience.

365 days

We are waiting for your call for 365 days, providing you with services such as purchase and support.

3000 customers

More than 3,000 customers purchase our equipment and are satisfied with the equipment and service.

10000 experiments

Our factory has conducted more than 10,000 innovative experiments since its inception.

Only to produce the most suitable equipment for the customer.