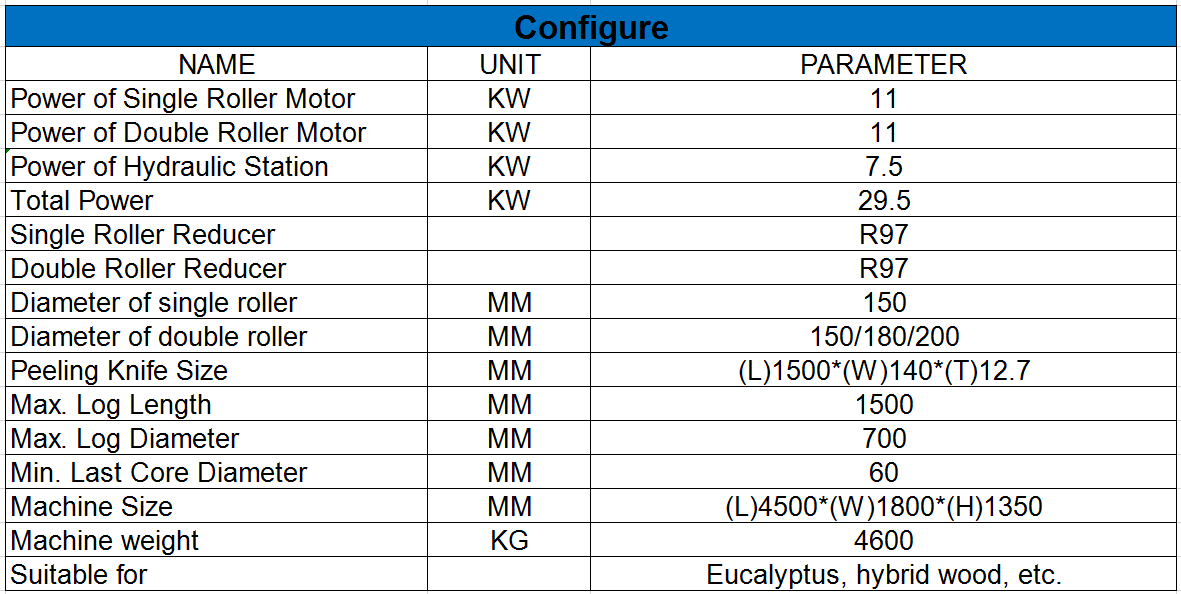

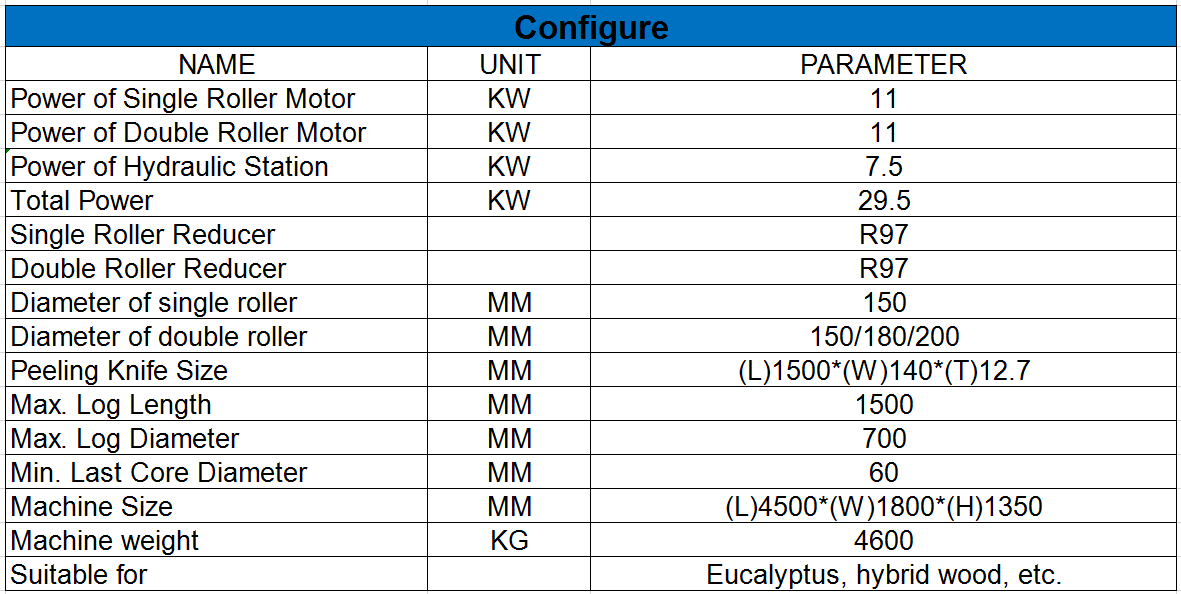

| Total prower: | |

|---|---|

| Maximum log length: | |

| Max. Log Diameter: | |

| Availability: | |

| Quantity: | |

CS-4ZR97(L)

Changsheng

8465960000

Plywood Machine 4 Feet Heavy Duty Log Debarker

Shandong changsheng machinery has been engaged in the research, development, manufacture, installation and maintenance of machinery and parts for plywood stripping and plywood manufacturing for more than 20 years.

This log debarker machine has air-conditioning system and thermal protection function. It is mainly used in India or other hot countries to prevent hydraulic oil from overheating. The equipment runs more stable and has lower noise. It is suitable for

rounding and peeling processes of hardwood such as eucalyptus.

1.Increase of single and double roll’s diameter, improving the speed of remove skin.

2.Single, double roll surface with chrome plating, improve wear-resisting of roller.

3.The hydraulic feeding mechanism, a cutter, rapid, and feed pressure can be adjusted and display, adapt to a different wood.

4.Simple operation, convenient maintenance, requirements for operators, and workers are not high technology.

5.With hydraulic feeding system, it can work quickly and efficiently.

6.One debarker can supply two peeling machines. It can save the original manual peeling and rounding procedure, saving 5-6workers.

7.This log debarker machine has air-conditioning system and thermal protection function. It is mainly used in India or other hot countries to prevent hydraulic oil from overheating.

Normally, one log debarking machine can provide round logs for two veneer peeling machines.

Pre-sale services:

1) Provide free consultation of the equipment.

2) Provide the standard device and the flow chart.

3) According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After-sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.

4) Door to door service is possible .

In terms of production technology, our company has ten senior engineers, more than 30 technicians, and more than 20 machine innovation patents. In terms of production equipment, our company is equipped with plasma cutting machines, laser cutting machines, Lincoln brand carbon dioxide protection welding machines and other welding and cutting equipment. And we have established friendly business relationship with famous brands spare parts supplier such as Siemens Motor, WEG Motor, Delta PLC, Inovance Inverter etc.

Our main products include log feeding machine ,plywood veneer peeling machine, log debarker , automatic veneer stacker,knife grinder machine ,veneer dryer and whole factory production line customization and parts, including rotary cutter, rubber roller, conveyor belt and so on.

Since its establishment, the company has more than 20 years of experience in the manufacture of rotary cutting machines.Our company provides customers with 24-hour service. We have exported to Canada, Mexico, Brazil, Russia, India, Indonesia, Vietnam, Ethiopia, Gabon and other more than 30 countries.Our plywood machine have been approved by our customers.

Changsheng Wood Machinery comes from China, serves all the world!

Plywood Machine 4 Feet Heavy Duty Log Debarker

Shandong changsheng machinery has been engaged in the research, development, manufacture, installation and maintenance of machinery and parts for plywood stripping and plywood manufacturing for more than 20 years.

This log debarker machine has air-conditioning system and thermal protection function. It is mainly used in India or other hot countries to prevent hydraulic oil from overheating. The equipment runs more stable and has lower noise. It is suitable for

rounding and peeling processes of hardwood such as eucalyptus.

1.Increase of single and double roll’s diameter, improving the speed of remove skin.

2.Single, double roll surface with chrome plating, improve wear-resisting of roller.

3.The hydraulic feeding mechanism, a cutter, rapid, and feed pressure can be adjusted and display, adapt to a different wood.

4.Simple operation, convenient maintenance, requirements for operators, and workers are not high technology.

5.With hydraulic feeding system, it can work quickly and efficiently.

6.One debarker can supply two peeling machines. It can save the original manual peeling and rounding procedure, saving 5-6workers.

7.This log debarker machine has air-conditioning system and thermal protection function. It is mainly used in India or other hot countries to prevent hydraulic oil from overheating.

Normally, one log debarking machine can provide round logs for two veneer peeling machines.

Pre-sale services:

1) Provide free consultation of the equipment.

2) Provide the standard device and the flow chart.

3) According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After-sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.

4) Door to door service is possible .

In terms of production technology, our company has ten senior engineers, more than 30 technicians, and more than 20 machine innovation patents. In terms of production equipment, our company is equipped with plasma cutting machines, laser cutting machines, Lincoln brand carbon dioxide protection welding machines and other welding and cutting equipment. And we have established friendly business relationship with famous brands spare parts supplier such as Siemens Motor, WEG Motor, Delta PLC, Inovance Inverter etc.

Our main products include log feeding machine ,plywood veneer peeling machine, log debarker , automatic veneer stacker,knife grinder machine ,veneer dryer and whole factory production line customization and parts, including rotary cutter, rubber roller, conveyor belt and so on.

Since its establishment, the company has more than 20 years of experience in the manufacture of rotary cutting machines.Our company provides customers with 24-hour service. We have exported to Canada, Mexico, Brazil, Russia, India, Indonesia, Vietnam, Ethiopia, Gabon and other more than 30 countries.Our plywood machine have been approved by our customers.

Changsheng Wood Machinery comes from China, serves all the world!